PPGI: Galvanized Painted Sheets

Table of Contents

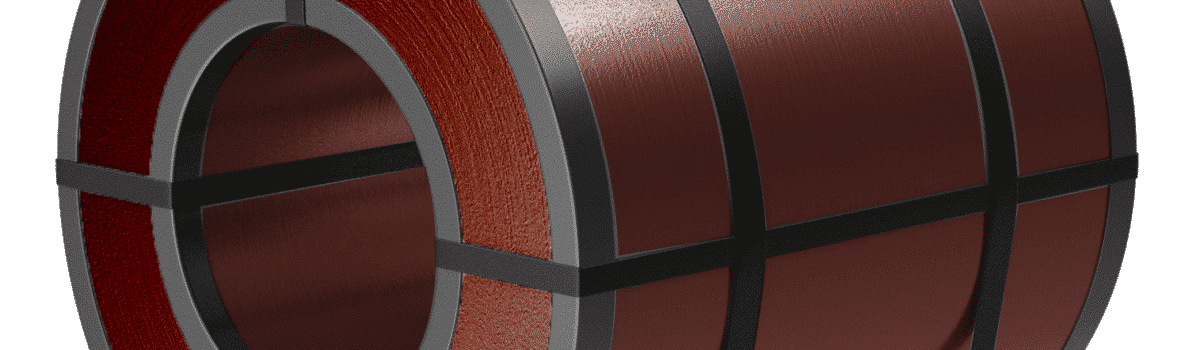

Introduction to PPGI

Pre-Painted Galvanized Iron (PPGI) sheets are a revolutionary product in the construction and manufacturing industries. These sheets are essentially galvanized iron that is first coated with zinc to provide a robust protective layer and then painted with various color options. This process not only enhances the aesthetic appeal of the sheets but also significantly improves their durability and resistance to corrosion.

Manufacturing Process

Galvanization

- Base metal (typically cold-rolled steel) is immersed in a molten zinc bath.

- Zinc coating offers excellent protection against rust and environmental factors.

Chemical Conversion Coating

- Improves adhesion of the paint layers.

Painting

- Primer ensures the topcoat adheres well.

- Topcoat provides color and additional protection.

- Popular colors: RAL9002 (Grey White), RAL3009 (Oxide Red), RAL7016 (Anthracite Grey).

Protective Film

- Shields the painted surface during handling and installation.

- Ensures a perfect appearance free from scratches.

The combination of galvanization, high-quality paint, and a protective film makes PPGI an incredibly versatile and reliable material for a wide range of applications.

Technology and Durability of PPGI Sheets

Pre-painted galvanized iron (PPGI) sheets represent a pinnacle of modern material technology, combining advanced processes to ensure superior durability and versatility.

Key Features

- Primer Paint: Enhances adhesion and provides an additional barrier against environmental stressors.

- Polyethylene Terephthalate (PET) Film Layer: Fortifies the steel surface and provides aesthetic appeal.

- PVC-Based Topcoat: Boosts flexibility and scratch resistance.

- Plastisol Coating: Exceptional durability and resistance to weathering and UV radiation.

The combination of primer paint, PET film, and plastisol coating ensures a product that is not only visually appealing but also highly durable.

Diverse Applications of Pre-Painted Galvanized Sheets

Pre-Painted Galvanized Iron (PPGI) sheets have gained remarkable traction across various industries due to their exceptional blend of durability and aesthetic appeal.

Applications

Construction Industry

- Roofing and cladding.

- Available in rolls, sheets, trapezoidal, corrugated, and embossed shapes.

Manufacturing of Household Appliances and Furniture

- Ideal for kitchen appliances and cabinetry.

Automotive Industry

- Used for both structural and decorative purposes.

Industrial Storage Solutions

- Durable and visually appealing shelving units, racks, and containers.

Aesthetics and Protection: The Dual Advantage of PPGI

Pre-painted galvanized iron (PPGI) sheets offer a unique combination of aesthetic appeal and robust protection.

Benefits

- Aesthetic Appeal

- Diverse color options for creative architectural designs.

- Durability

- Zinc coating provides a formidable barrier against corrosion.

- Protective film or paint layer enhances resistance to environmental factors.

The dual advantage of aesthetics and protection makes PPGI sheets an ideal material for a wide range of applications, from roofing to interior décor.

Contact Us

For those interested in purchasing high-quality PPGI sheets, it is essential to choose a reputable supplier. Our team of experts is dedicated to delivering premium galvanized painted sheets with zinc coating, ensuring competitive prices and timely delivery. Contact us to discuss your project requirements and benefit from our expertise in providing durable and aesthetically pleasing PPGI solutions tailored to your specific needs.

Send us a message!

At Steeling.NET, we are committed to providing unparalleled service and expertise. If you have any questions about our carbon steel sheets or would like to discuss your specific project needs with our skilled professionals, please contact us.

info@steeling.net

WATCH ON SOCIAL MEDIA

Frequently Asked Questions (FAQs)

What is PPGI?

PPGI stands for Pre-Painted Galvanized Iron, which are galvanized iron sheets coated with zinc and painted for enhanced durability and aesthetic appeal.

How are PPGI sheets manufactured?

PPGI sheets are made by galvanizing cold-rolled steel, applying a chemical conversion coating, and then painting with a primer and topcoat.

What are the benefits of using PPGI sheets?

PPGI sheets offer excellent corrosion resistance, durability, a wide range of color options, and enhanced aesthetic appeal.

Where can PPGI sheets be used?

PPGI sheets are versatile and can be used in roofing, cladding, automotive parts, household appliances, furniture, and industrial storage solutions.

How long do PPGI sheets last?

With proper maintenance, PPGI sheets can last 20-30 years or longer due to their protective coatings.

What color options are available for PPGI sheets?

PPGI sheets are available in numerous color options, including popular choices like RAL9002 (Grey White), RAL3009 (Oxide Red), and RAL7016 (Anthracite Grey).

Are PPGI sheets environmentally friendly?

Yes, PPGI sheets are recyclable and their long lifespan reduces the need for frequent replacements, making them environmentally friendly.

Can PPGI sheets withstand extreme weather conditions?

Yes, the galvanized and painted finishes make PPGI sheets highly resistant to extreme weather conditions, including UV radiation, moisture, and chemicals.

How do PPGI sheets enhance architectural designs?

PPGI sheets offer a wide range of colors and finishes, providing architects and designers with flexibility to create visually appealing and durable structures.

Where can I purchase high-quality PPGI sheets?

You can purchase high-quality PPGI sheets from reputable suppliers who offer a range of options, competitive prices, and expert guidance to meet your specific needs.