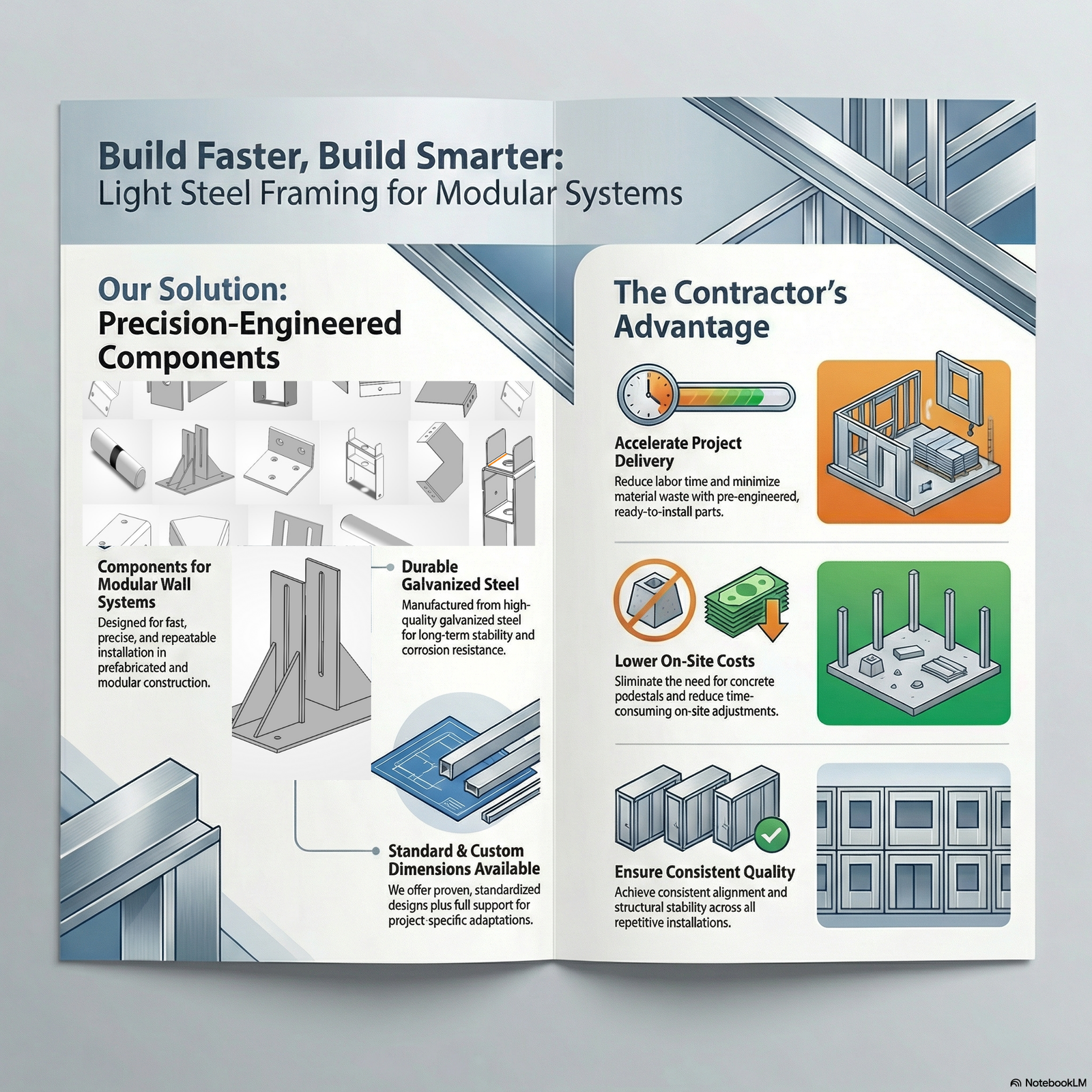

How Light Steel Framing Components Reduce Construction Costs in Modular Wall Systems

In today’s construction industry, reducing costs without compromising structural performance is a top priority. Rising material prices, labor shortages, and tight project schedules have pushed contractors and developers to seek smarter building systems. One of the most effective solutions is the use of light steel framing components and accessories for modular wall systems.

This article explains how light steel framing systems help construction projects achieve significant savings in cost, time, and labor, while maintaining strength, flexibility, and long-term reliability.

What Are Light Steel Framing Components?

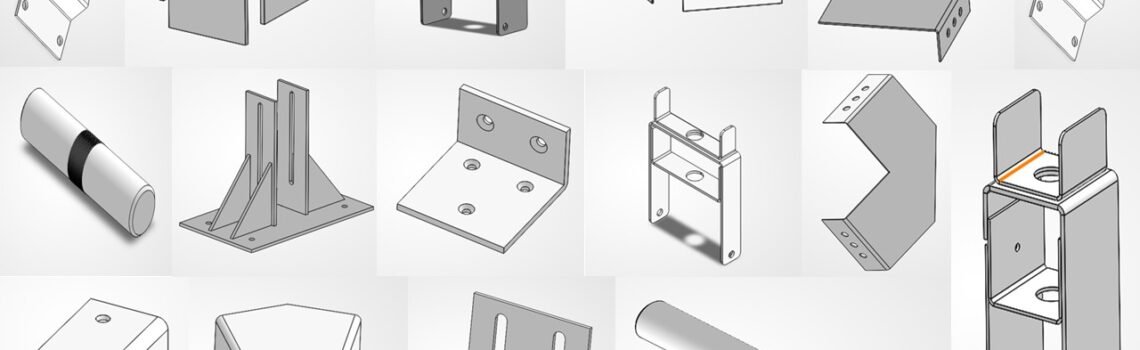

Light steel framing (LSF) components are cold-formed steel elements designed for modular and prefabricated wall systems. These components are commonly used in residential, commercial, and industrial buildings where speed and precision are essential.

At Steeling, our adjustable steel support and mounting components are engineered to simplify installation and enhance structural efficiency in modular wall assemblies.

👉 Explore the product range here:

Light Steel Framing Components & Accessories

Reduced Material Waste = Lower Project Costs

Traditional construction methods often result in excessive material waste due to on-site cutting and fitting. Light steel framing systems, on the other hand, are precision-manufactured, ensuring consistent dimensions and minimal waste.

Cost-saving benefits:

- Optimized material usage

- Less scrap and rework

- Predictable material quantities

This directly reduces raw material costs and improves overall budget control.

Faster Installation Means Lower Labor Expenses

Labor is one of the most expensive components of any construction project. Light steel framing components are designed for fast, modular assembly, requiring fewer skilled labor hours compared to conventional methods.

How LSF systems save labor costs:

- Pre-engineered components reduce on-site adjustments

- Lightweight elements are easier to handle

- Faster wall assembly shortens construction timelines

Shorter build times also mean lower site overhead costs, making modular wall systems highly attractive for large-scale projects.

Adjustable Components Increase Flexibility and Efficiency

One of the biggest advantages of Steeling’s adjustable steel support and mounting components is their adaptability. Adjustable systems allow installers to compensate for minor alignment issues without costly modifications.

Why this matters financially:

- Fewer installation errors

- Reduced need for corrective work

- Improved productivity on site

This flexibility translates into smoother workflows and fewer unexpected expenses.

Lightweight Steel = Savings in Transportation & Handling

Compared to traditional structural materials, light steel framing components offer a high strength-to-weight ratio. This reduces transportation costs and simplifies on-site logistics.

Additional savings include:

- Lower shipping costs

- Easier storage on site

- Reduced need for heavy lifting equipment

For international projects or large developments, these savings can be substantial.

Long-Term Cost Benefits: Durability & Low Maintenance

Light steel framing systems are highly resistant to:

- Moisture

- Pests

- Warping and cracking

This durability minimizes long-term maintenance and repair costs, making them a cost-effective solution over the building’s lifecycle.

Ideal for Modular & Prefabricated Construction Projects

Modular construction relies on speed, precision, and repeatability—areas where light steel framing truly excels. Using standardized, high-quality steel components ensures:

- Consistent quality across modules

- Faster project delivery

- Reduced risk of delays and cost overruns

This makes light steel framing systems particularly attractive for hotels, residential complexes, commercial buildings, and industrial facilities.

Why Choose Steeling for Light Steel Framing Solutions?

At Steeling, we manufacture and supply high-quality light steel framing components designed to support efficient, cost-effective construction projects worldwide.

By integrating these components with our broader capabilities—such as sheet metal fabrication, laser cutting, and machining—we help clients streamline their supply chain and reduce total project costs.

👉 Learn more about our fabrication expertise:

👉 Ready to optimize your construction project?

Contact Steeling for technical support or a quotation.

Final Thoughts

Light steel framing components and accessories offer a powerful combination of cost savings, speed, and durability. For modern construction projects—especially modular wall systems—they represent a smart investment that delivers both immediate and long-term financial benefits.

By choosing the right components and a reliable manufacturing partner, contractors and developers can significantly improve project efficiency while keeping costs under control.